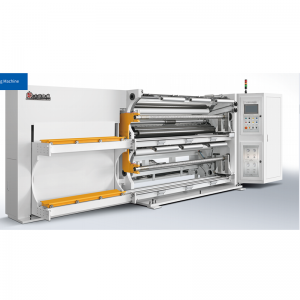

SLM-B High Speed Slitting Machine Automatic Slitting Machine

1.Mochine ona o sebelisoa haholo-holo ho khaola pampiri, filimi ea laminated, foil ea aluminium, joalo-joalo.

2.Mochine oohle o laoloa ke PLC (li-vector tse peli tsa li-vector), sebopeho sa mochine oa motho, ts'ebetso ea skrine ea skrine.

Karolo ea 3.Unwinder e hlomella ka brake ea moea ea Italia RE, e hlokomela ka ho bala ka mokhoa o itekanetseng oa PLC, hammoho le taolo e tsitsitseng ea tsitsipano bakeng sa ho phutholoha.

Karolo ea 4.Transmission e sebelisa motlakase oa ho fetola maqhubu a vector, hlokomela taolo ea lebelo la mohala oa kamehla.

5.Unwinder shaftless.ka hydraulic auto loading, vice- clamps motlakase.

Li-winders tsa 6.Re li laoloa ke li-motors, Sesebelisoa se feletseng sa ho theola likoloi se kenyelelitsoe ka mochine.

7.Ho seta methara e ikemetseng, ho bala mithara ea koloi, ho emisa ka koloi, joalo-joalo.

Sesebelisoa sa ho lokisa phoso sa 8.EPC se nepahetse ho netefatsa ho nepahala.

| Boholo ba bophara ba lintho tse bonahalang | 1200-2500mm I |

| Bophahamo bo phahameng ba ho phutholoha | Φ1000/1300mm |

| Bophahamo bo phahameng ba ho khutlisa morao | 6600 limilimithara |

| Lebelo | 450-600m/min |

| Matla | 13kw |

| Kakaretso ea boholo(LX WX H) | 1800X2800X1600mm |

| Boima ba 'mele | 5500kg |

Sesepa sa othomathike sa lebelo le phahameng ke sekotoana sa mochini o feto-fetohang o etselitsoeng ho seha lirolo tse kholo tsa thepa ka bophara bo bonyenyane, bo laolehang haholoanyane.E fana ka melemo e mengata ho feta mekhoa ea ho itšeha ka letsoho, ho kenyelletsa tlhahiso e eketsehileng, ho nepahala ho ntlafalitsoeng le litšila tse fokotsehileng.Ha re hlahlobeng ka botebo likarolo, melemo le ts'ebeliso ea mochini ona o tsotehang.

Li-slitters tsa lebelo le holimo li tsebahala ka lebelo la tsona le ikhethang la ho itšeha.Ka theknoloji e tsoetseng pele ea makoloi le litsamaiso tse nepahetseng tsa taolo, li ka fihlela lebelo la ho fihla ho limithara tse 1000 ka motsotso, li feta bokhoni ba mekhoa ea khale ea matsoho.Bokhoni bona ba lebelo le phahameng bo nolofalletsa ho sebetsa ka potlako ha lisebelisoa tse ngata, ho boloka nako le litšenyehelo tsa basebetsi.

E 'ngoe ea likarolo tse ka sehloohong tsa slitter ea othomathike ke bokhoni ba ho etsa ts'ebetso ea slitting ka bo eona.Sena se bolela hore hang ha mochine o se o hlongoa le ho hlophisoa ho ea ka tekanyo e lakatsehang, o ka iphepa, oa khaola le ho otlolla thepa ntle le ho kenella kamehla.Bokhoni bona ba boits'oaro bo lokolla lisebelisoa tsa bohlokoa tsa batho, ho lumella opareitara ho tsepamisa maikutlo mesebetsing e meng ea bohlokoa ha mochini o sebetsa ka thata ho etsa mosebetsi oo o o filoeng.

Ho nepahala ho bohlokoa lits'ebetsong tsa indasteri, 'me li-slitters tsa lebelo le holimo li fana ka mokhoa o nepahetseng o ikhethang.E na le li-sensor tsa morao-rao le li-control, mechini ena e khona ho fumana mamello ea ho itšeha e tlase joalo ka ± 0.1mm.Boemo bona ba ho nepahala bo tiisa ho tsitsisa sehlahisoa sa ho qetela, ho ntlafatsa boleng le khotsofalo ea bareki.

Molemo o mong oa bohlokoa oa li-slitters tse ikemetseng ke bokhoni ba tsona ba ho fokotsa litšila tsa thepa.Mekhoa e tloaelehileng ea ho itšeha ka letsoho e atisa ho hlahisa masala a maholo le li-offcuts, tse bakang litšenyehelo tse eketsehileng tsa thepa le ho eketseha ha tšusumetso ea tikoloho.Ka lehlakoreng le leng, li-slitters tsa othomathike li ntlafatsa ts'ebeliso ea lisebelisoa ka ho fokotsa bophara ba moqolo ho bapisa boholo bo hlokahalang.Phokotso ea litšila e boloka litšenyehelo 'me e kenya letsoho molemong oa ts'ebetso ea tlhahiso.

Masimo a ts'ebeliso ea mochini o otlolohileng oa lebelo le phahameng a pharalletse ebile a fapane.Indastering ea lipampiri, mechini ena e sebelisoa ho fetolela lirolo tse kholo tsa pampiri hore e be bophara bo moqotetsane ho latela litlhoko tse itseng.Baetsi ba lifilimi ba sebelisa li-slitters tse ikemetseng ho sebetsana le lirolo tse kholo tsa lifilimi ka bophara bo nyane bakeng sa ho paka kapa ho hatisa.Ka mokhoa o ts'oanang, liindasteri tsa masela le masela li sebelisa mokhoa ona ho seha lesela hore e be likhoele kapa meqolo e loketseng tlhahiso ea liaparo.Esita le indasteri ea tšepe e ruile molemo ho li-slitters tse iketsang, li li sebelisa ho khaola litšepe ka likhoele tse tšesaane bakeng sa lisebelisoa tse fapaneng.